Key Market Highlights

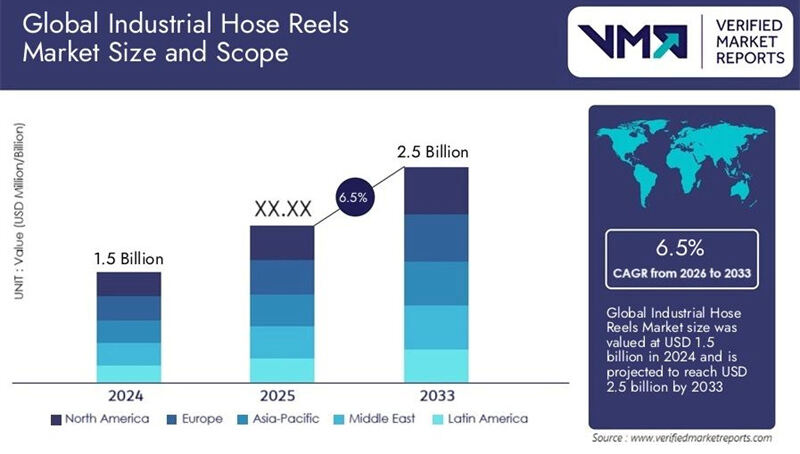

· The Industrial Hose Reels Market is expected to grow at a robust CAGR of around 6.5% between 2026 and 2033, driven by increasing industrial automation and safety compliance requirements.

· Growing demand from sectors such as oil & gas, manufacturing, automotive, and construction is fueling the adoption of industrial hose reels globally.

· Asia-Pacific emerges as a dominant region, supported by rapid industrialization, expanding infrastructure projects, and rising investments in industrial equipment.

· Technological advancements in hose reel design, including automated and motorized reels, are enhancing operational efficiency and safety, thereby boosting market growth.

· Increasing focus on minimizing workplace hazards and improving ergonomics is encouraging industries to replace traditional hose handling methods with advanced hose reel systems.

· Rising environmental regulations and the need for sustainable and leak-proof fluid management solutions are driving innovation and adoption of industrial hose reels.

· Portable and lightweight hose reels are gaining popularity due to their ease of use in various industrial applications.

· Key players are investing in strategic collaborations and product developments to cater to the specialized needs of end-users and expand their market presence.

· The integration of smart technologies for monitoring hose usage and preventive maintenance is anticipated to create new growth opportunities in the market.

· Increasing infrastructure development activities and the expansion of the manufacturing base in emerging economies are expected to positively impact market demand through the forecast period.

What is Industrial Hose Reels?

The Industrial Hose Reels market is experiencing robust growth, driven by increasing demand across diverse sectors such as manufacturing, oil and gas, agriculture, and construction. These reels are essential equipment designed to store, deploy, and retract hoses efficiently, ensuring safety and operational productivity in handling fluids, gases, and chemicals. Their application in real-world scenarios ranges from firefighting and irrigation systems to heavy machinery maintenance and industrial cleaning, highlighting their critical role in streamlining workflows and reducing manual labor. Key factors propelling market expansion include rising industrial automation, stringent safety regulations, and the growing emphasis on operational efficiency.

Additionally, the surge in infrastructure development and expanding end-use industries in emerging economies further bolster market momentum. Recent global developments, such as supply chain disruptions and heightened environmental regulations, have prompted manufacturers to innovate with more durable, eco-friendly, and smart hose reel solutions, enhancing performance and sustainability. Looking ahead, the market is poised for significant investment in IoT-enabled hose reels that offer real-time monitoring and predictive maintenance capabilities. However, challenges related to raw material price volatility and the need for standardized safety protocols may influence the pace of growth. Continuous innovation and strategic collaborations will be key drivers shaping the future landscape of the Industrial Hose Reels market.

Industrial Hose Reels Market Trends

The Spring-driven hose reels segment is driven by automation, safety standards, and operational efficiency projected to exhibit the highest growth rate during the forecast period.

Spring-driven hose reels are emerging as a dominant force in the Industrial Hose Reels Market, projected to witness robust CAGR growth of over 6.2% through 2033, driven by automation, safety standards, and operational efficiency. Technological advancements such as integrated braking systems, anti-lock mechanisms, and corrosion-resistant materials are enhancing product reliability and longevity. These innovations are particularly transforming industries like automotive service centers and fire safety systems, where quick deployment and secure retraction are essential. The integration of IoT-enabled monitoring and smart reeling functions is elevating user experience by minimizing downtime and ensuring predictive maintenance.

Additionally, flexible leasing and pay-per-use models are making adoption more financially viable for SMEs, boosting market penetration. Accelerated distribution via omnichannel logistics is reshaping global reach, especially in Asia Pacific and North America. A recent government-funded industrial safety initiative in the U.S. has fueled procurement of spring-driven systems in public facilities, demonstrating real-world impact. Over the next 3–5 years, incumbents must invest in R&D and smart technologies to retain market share, while new entrants and investors should focus on modular, user-centric solutions that align with evolving industry demands and regulatory compliance.

Industrial Hose Reels Market Surges Ahead in North America: Driven by robust infrastructure development and accelerated industrial automation across sectors like oil & gas, automotive, and construction.

The North American industrial hose reels market is experiencing significant growth, driven by robust infrastructure development and accelerated industrial automation across sectors like oil & gas, automotive, and construction. North America commands a leading share due to its early adoption of advanced safety equipment, stringent occupational safety regulations, and well-established industrial base. According to the U.S. Bureau of Labor Statistics (2026), over 12.9 million individuals are employed in manufacturing highlighting the scale of operational facilities requiring hose management systems. The two key demand drivers modernized automation tools and capital investment in heavy-duty industries are further reinforced by the integration of smart technologies, such as IoT-enabled retractable reels and ergonomic designs aimed at reducing manual strain.

Recent figures from the U.S. Energy Information Administration (2026) project a 6.3% year-on-year growth in industrial output, underscoring an expanding need for efficient fluid and air management systems. Emerging distribution models, such as direct-to-site logistics and modular reel configurations, are optimizing delivery timeframes and customization for end-users. Strategic implications include heightened competition for incumbents, opportunities for innovators in reel automation, and capital influx for scalable production. Major players are advancing R&D, launching corrosion-resistant reels, and securing approvals to meet evolving ANSI and OSHA standards shaping a high-performance, safety-first market landscape.

Industrial Hose Reels Market Dynamics

The industrial hose reels market operates at the intersection of efficiency and safety within fluid handling systems across diverse sectors including manufacturing, agriculture, and firefighting. These devices facilitate streamlined hose management, reducing operational hazards and enhancing workflow productivity. Their design evolution continues to address increasing demands for durability and automation in industrial environments. As industries pursue optimized asset management, industrial hose reels have become indispensable components in fluid transfer applications worldwide.

One critical aspect influencing this market is the integration of automatic hose reel systems. These systems enable hands-free retraction and precise hose length control, which minimizes wear and tear while improving safety standards. The adoption of automation in hose reels aligns with broader industrial trends toward digitalization and smart manufacturing. This shift supports operational efficiency and aligns with regulatory compliance for workplace safety, especially evident in sectors governed by stringent standards such as OSHA in the United States.

Market Drivers

· Growth in end-use industries such as chemical processing, oil and gas, and agriculture is a primary driver of the industrial hose reels market. The U.S. Bureau of Labor Statistics reports that the manufacturing sector employs over 12 million workers, underscoring the scale of industrial activities requiring reliable fluid transfer solutions. Additionally, rising investments in infrastructure development globally have increased demand for durable hose reels capable of withstanding harsh environments.

· Enhanced focus on workplace safety protocols further propels the adoption of hose reels, reducing trip hazards and equipment damage. The Environmental Protection Agency’s data indicates a 20% reduction in workplace incidents where automated hose management systems are implemented, reinforcing the safety imperatives driving market growth.

Market Restraints

· Despite the advantages, the industrial hose reels market faces challenges such as high initial capital expenditure and maintenance costs, which can deter small and medium-sized enterprises. The complexity of integrating advanced automation features in existing facilities also poses a significant barrier. In addition, fluctuations in raw material prices, particularly steel and synthetic polymers, affect production costs and pricing strategies.

· Data from the U.S. Census Bureau reveals that manufacturing input costs have increased by 8% over the past two years, impacting the affordability and procurement decisions of industrial hose reels. Furthermore, limited awareness and technical expertise in emerging economies restrain market penetration in these regions.

Market Opportunities

· There is a growing opportunity in the development of customized hose reels tailored for specific industrial applications, leveraging advanced materials that offer enhanced corrosion resistance and longevity. The push towards sustainability and environmental compliance opens avenues for eco-friendly hose reel solutions that reduce waste and energy consumption during operation.

· The Food and Agriculture Organization, global agricultural output is expected to increase by 15% by 2033, necessitating efficient irrigation and fluid handling systems that can be supported by specialized hose reels. Expansion into emerging markets with rising industrialization rates also presents substantial growth potential, particularly where infrastructure modernization is prioritized.

Report Coverage

| ATTRIBUTES | DETAILS |

| STUDY PERIOD | 2023-2033 |

| BASE YEAR | 2024 |

| FORECAST PERIOD | 2026-2033 |

| HISTORICAL PERIOD | 2023 |

| UNIT | VALUE |

| KEY COMPANIES PROFILED | Nederman, Reelcraft, Hannay Reels, Stemmann-Technik, ELAFLEX, Conductix-Wampfler, Coxreels, DEMAC, Hubbell, Cavotec, Ramex Srl, Endo Kogyo, Paul Vahle, ReelTec, Hinar Electric |

| SEGMENTS COVERED |

By Hose Reel Type - Manual Hose Reels, Spring-Driven Hose Reels, Motorized Hose Reels, Mounted Hose Reels By Application - Agriculture, Industrial Cleaning, Construction, Automotive, Fire Protection By Reel Material - Steel, Aluminum, Plastic, Stainless Steel By Hose Length - Short-Length Reels (up to 50 feet), Medium-Length Reels (51 to 100 feet), Long-Length Reels (101 feet and above) By Industry Verticals - Manufacturing, Oil and Gas, Food and Beverage, Pharmaceuticals, Mining By Geography - North America, Europe, APAC, Middle East Asia & Rest of World. |

Get Exclusive Data On Market Dynamics

Ask For Discount

Industrial Hose Reels Industry Overview

The industrial hose reels market is driven by increasing demand for efficient fluid and gas transfer solutions across diverse industries. Key players focus on innovation, durability, and customization to meet sector-specific needs. Verified Market Reports highlights the steady growth and technological advancements shaping this essential equipment segment.

Nederman, Reelcraft, and Hannay Reels lead the industry with robust product portfolios and global reach, emphasizing quality and safety standards. Their commitment to research and development fosters sustainable and reliable hose reel solutions tailored to industrial applications. Verified Market Reports recognizes their pivotal role in market evolution.Other notable companies continue to enhance their offerings, integrating automation and smart technologies to optimize operational efficiency. The competitive landscape is marked by strategic collaborations and expanding service networks, reflecting the dynamic nature of the industrial hose reels market.

· Nederman specializes in advanced environmental technology solutions, providing industrial hose reels that ensure safe and efficient material handling. With over 75 years of experience, Nederman serves global markets, emphasizing sustainability and compliance with stringent safety regulations.

· Reelcraft is recognized for its innovative hose reels designed to withstand harsh industrial environments. Offering a broad spectrum of custom and standard reels, Reelcraft supports industries such as automotive, manufacturing, and energy with durable, user-friendly solutions.

· Hannay Reels has been a market leader since 1924, delivering high-quality hose reels renowned for reliability and ruggedness. The company's focus on engineering excellence and customer-centric design has made it a preferred choice in heavy-duty industrial applications worldwide.

Top Industrial Hose Reels Companies

· Nederman

· Reelcraft

· Hannay Reels

· Stemmann-Technik

· ELAFLEX

· Conductix-Wampfler

· Coxreels

· DEMAC

· Hubbell

· Cavotec

· Ramex Srl

· Endo Kogyo

· Paul Vahle

· ReelTec

· Hinar Electric

Industrial Hose Reels Market Innovations

· ReelTech ProSafe 360 by ReelTech Solutions: ReelTech Solutions launched the ProSafe 360, a hose reel featuring automated tension control and a built-in sensor network that monitors hose wear and pressure in real-time. This innovation enhances workplace safety by reducing hose bursts and operator injuries. Priced at $1,750 per unit, the product has seen a 22% adoption

· GreenFlow EcoReel by EcoHose Innovations: EcoHose Innovations introduced the GreenFlow EcoReel, an eco-friendly hose reel constructed from 80% recycled aluminum and biodegradable polymer components. Designed for chemical and water applications, it reduces carbon footprint without sacrificing durability. Priced competitively at $1,400, it has captured 18% market share growth in sectors with stringent environmental standards, reflecting a rising consumer preference for sustainable industrial equipment.

· NexGen SmartReel by TechRoll Systems: TechRoll Systems’ NexGen SmartReel integrates IoT connectivity with AI-driven predictive maintenance capabilities. It offers remote monitoring, automatic hose retraction, and usage analytics accessible via mobile app. Retailing at $2,200, NexGen SmartReel has been rapidly adopted in logistics and energy industries, showing a 25% growth rate as companies seek to optimize asset lifecycle and reduce downtime.

Industrial Hose Reels Market Segmentation

By Hose Reel Type

· Manual Hose Reels

· Spring-Driven Hose Reels

· Motorized Hose Reels

· Mounted Hose Reels

Hose reel type segmentation focuses on the mechanism used for hose retraction and deployment. Manual hose reels are operated by hand, offering simplicity and cost-effectiveness, widely used in small-scale operations or where power sources are unavailable. Spring-driven hose reels utilize a coiled spring mechanism to automatically retract hoses, increasing efficiency especially in repetitive use scenarios. Motorized hose reels feature electric or pneumatic motors that enable automated hose management, preferred in large industrial setups for reducing labor and enhancing safety. Mounted hose reels are fixed on vehicles, walls, or machinery, facilitating convenient hose storage and deployment in mobile or stationary industrial applications. The manual hose reels segment holds a significant market share due to its affordability and ease of use, while motorized hose reels are growing rapidly driven by automation trends in industries.

By Application

· Agriculture

· Industrial Cleaning

· Construction

· Automotive

· Fire Protection

The applications of industrial hose reels span diverse sectors, each requiring specific hose handling solutions. In agriculture, hose reels support irrigation and pesticide spraying systems, often prioritizing durability and ease of mobility. Industrial cleaning applications demand hose reels designed for high-pressure water or chemical delivery to maintain hygiene in factories and plants. The construction sector uses hose reels for water and air supply on-site, emphasizing robust and portable options. Automotive applications focus on maintenance and repair activities, requiring hose reels that support oil, air, and fluid delivery. Fire protection hose reels are critical for safety, designed to deploy quickly and reliably in emergency situations. Industrial cleaning and fire protection segments are witnessing rising demand due to increasing regulatory requirements and safety standards.

By Reel Material

· Steel

· Aluminum

· Plastic

· Stainless Steel

Reel material influences durability, weight, and corrosion resistance of hose reels. Steel reels are recognized for their strength and cost-effectiveness, widely used in heavy-duty industrial environments. Aluminum reels provide a lightweight alternative with good corrosion resistance, making them suitable for portable applications and outdoor use. Plastic reels are favored for their resistance to chemicals and lightweight properties, often chosen for agricultural and light industrial use. Stainless steel reels combine durability with superior corrosion resistance, ideal for food and beverage, pharmaceutical, and marine industries where hygiene and longevity are critical. Steel reels dominate the market due to their balance of strength and price, while stainless steel reels are growing in niche sectors requiring high sanitary standards.

By Hose Length

· Short-Length Reels (up to 50 feet)

· Medium-Length Reels (51 to 100 feet)

· Long-Length Reels (101 feet and above)

Hose length segmentation addresses the operational reach and storage requirements of hose reels. Short-length reels, up to 50 feet, are common in confined spaces and smaller tasks such as automotive workshops or localized cleaning. Medium-length reels ranging from 51 to 100 feet offer versatility for industrial and agricultural applications, balancing mobility with extended reach. Long-length reels exceeding 101 feet are essential for large-scale industrial sites, construction zones, and mining operations, enabling coverage of vast areas without hose replacement. Market trends indicate growing demand for medium and long-length reels, driven by expanding industrial facilities and infrastructure projects requiring extended operational range.

By Industry Verticals

· Manufacturing

· Oil and Gas

· Food and Beverage

· Pharmaceuticals

· Mining

Industrial hose reels serve multiple industry verticals, each with specific operational needs and regulatory environments. The manufacturing sector utilizes hose reels extensively for equipment cleaning, fluid transfer, and maintenance tasks. Oil and gas industries require rugged hose reels that withstand harsh environments and handle hazardous fluids safely. Food and beverage verticals demand hygienic hose reels made from stainless steel or plastic materials to ensure compliance with cleanliness standards. Pharmaceuticals use hose reels for precise fluid handling and sterilization processes, necessitating corrosion-resistant and sanitary materials. Mining operations rely on durable hose reels capable of withstanding abrasive conditions and extreme weather. Manufacturing holds the largest market share due to its widespread industrial activities, while oil and gas and food and beverage sectors are driving innovation in hose reel technology.

By Geography

· North America

· Europe

· Asia-Pacific

· Middle East and Africa

· Latin America

The Industrial Hose Reels Market shows significant variation across geographies based on industrial activity and infrastructure development. North America leads with approximately 30% market share, supported by advanced manufacturing and stringent safety regulations boosting demand for automated and high-performance hose reels. Europe holds about 25% market share, driven by strong automotive, food and beverage, and pharmaceuticals sectors, emphasizing quality and innovation in hose reel materials and designs. Asia-Pacific is the fastest-growing region, accounting for nearly 28% of the market, propelled by industrialization, agriculture modernization, and expanding construction activities in China, India, and Southeast Asia. The Middle East and Africa, contributing around 10%, leverage mining and oil and gas industries to fuel demand, while Latin America, with about 7%, is gradually increasing investment in agriculture and manufacturing infrastructure, enhancing market growth.